Process for Production of Sports Clothing

“Everything is easy when you know how to do it”

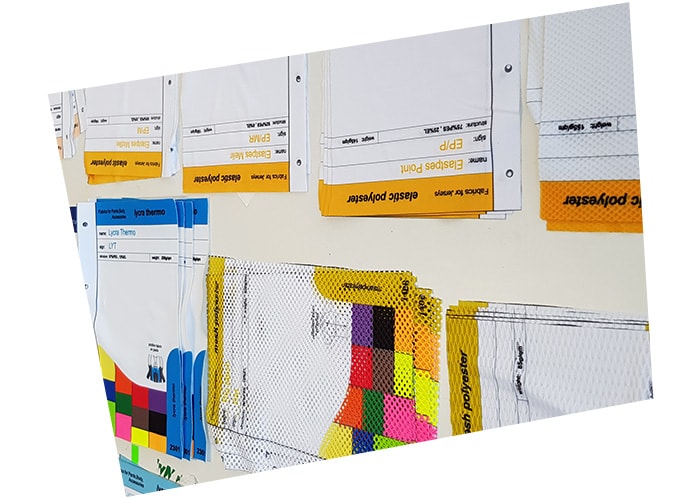

Product Development

At the beginning there is an idea, designing a new product. Followed by endless editing editing, prototyping and testing in practice. The finished cut is converted into an electronic form, all sizes are tested and the model is added to the collection.

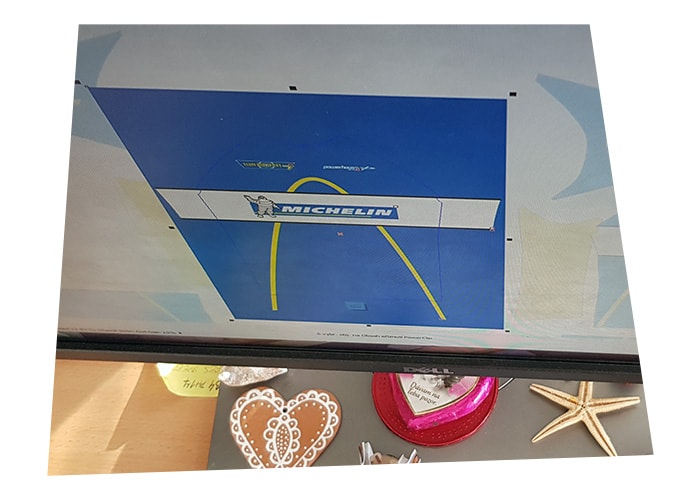

Graphics

The business case is agreed. Design approved. We will now insert and customize your design together with the logos to each model size.

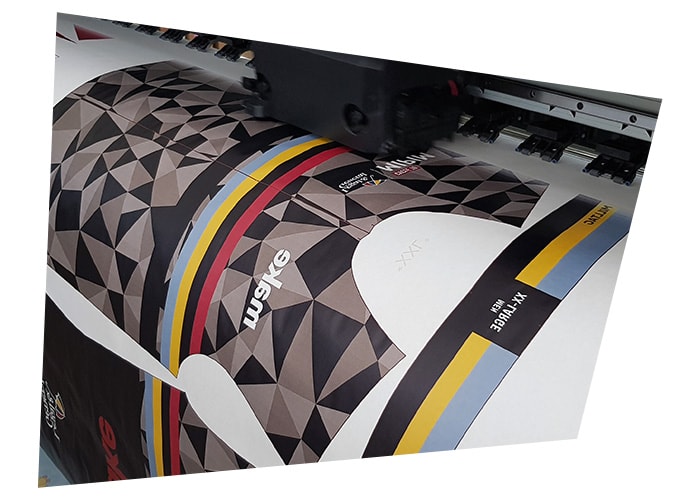

Printing

Pressing

Cutting

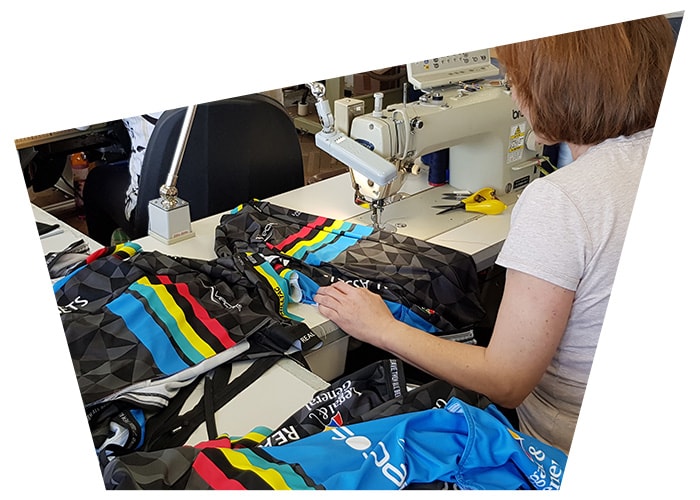

Sewing

Inspection

Delivery

Let’s Connect

Revamp your style, shop now! Explore our curated collection of clothing and sportswear, blending fashion and function. Elevate your wardrobe today.